Empowering Agriculture with Advanced Film Technology

The 3-Layer Mulch Film Plant from Shubham Extrusion is designed to deliver high-performance films with superior quality, efficiency, and sustainability. With over 27 years of expertise, we provide innovative solutions tailored for agricultural and industrial needs, helping you achieve excellence in film production.

Connect for Mulch Film Plant Connect for Mulch Film PlantIncorporate up to 40% recycle in the overall film, reducing raw material costs by 25%.in courier bag application

Precision-engineered components deliver optimal performance and reliability.

Fully customizable for specific application requirements.

Delivers 240–310 kg/hr for large-scale operations.

Excellent strength, gloss, and optical properties.

Compatible with LL/LDPE, HM/HDPE, EVA, and metallocene..

Lower energy consumption with advanced technology.

Scissor-type calibration cages and automated controls.

Plasma-nitride barrier screws and Japanese steel die heads.

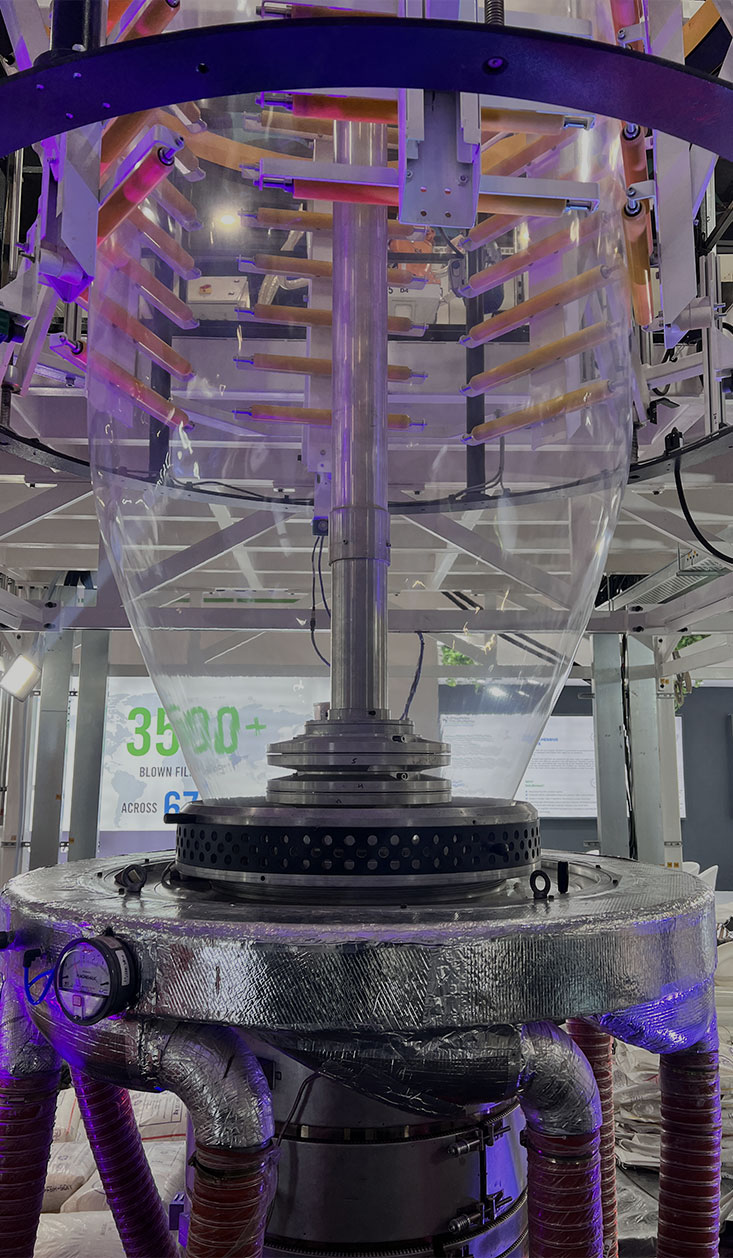

Our state of art IBC DIE Head is designed to maintain back pressure at peak output with Maximum overlaps Ensure excellent Melt uniformity & color uniformity over long run with Almost No dead Areas to Avoid degradation of Melt & gel generation in Long run

Ensure fastest changeover from color to Natural & Natural to color with Minimum changeover wastage

The 3-Layer Mulch Film Plant caters to a wide range of industries, producing films for both agricultural and industrial purposes:

General Purpose Film

Surface Protection Film

Tarpaulin Film

Lamination Film

Shrink Hood Film

FIBC Liners / Mattress Covers

Food Packaging Film

LD-Shrink Film

Milk Film

Stretch Film

Courier Bags

Water Packaging Film

Atta Film

Mulch Film

Agroshed Net Film

| Parameter | Specification |

|---|---|

| Polymer Compatibility | LL/LDPE, HM/HDPE, EVA, Metallocene |

| Thickness Range | 20 – 200 µ |

| Layflat Range | 1200 – 2100 mm |

| Output Capacity | 180 – 330 kg/hr |

| Layer Configuration | A-B-C (1:1:1 to 1:3:1 layer ratio) |

| Die Head | Taper lock mechanism, Japanese steel |

| Screw | Plasma-nitrided barrier screw (72–74 HRC) |

| Additional Features | Calibration cage, motorized controls, heat exchanger |

Our customers consistently share how impressed they are with the quality, consistency, and performance of our 3-Layer Mulch Film Plant. From streamlined operations to minimal maintenance, this machine is engineered to deliver measurable ROI from day one.

Operators appreciate the intuitive controls, while plant managers notice the improved film strength and precision layer distribution—critical in agricultural applications. Our clients highlight how the uniform film thickness and tight roll winding give them a competitive edge in the market.

What truly wins them over is the long-term reliability. Many report running the machine 24/7 with virtually no downtime. That level of trust only comes from equipment designed and built with care.

If you're looking to upgrade your mulch film production with confidence, this is the plant to invest in.

At Shubham Extrusion, we combine innovation, precision, and reliability to deliver world-class blown film solutions. Our 3-Layer Mulch Film Plant offers unmatched cost savings, superior quality, and versatile applications. With over 3500 global installations and dedicated customer support, we empower your production success.

Uncompromising Quality: Precision-engineered components deliver optimal performance and reliability.

Tailor-Made Configuration: Fully customizable to suit your specific application and production requirements.

In today’s competitive agricultural packaging industry, every rupee matters. Our 3-Layer Mulch Film Plant has been engineered not just to perform, but to maximize your ROI from day one.

Customers across India and more than 30 countries have chosen this machine for one simple reason: it delivers results.

Most mulch film producers struggle with rising raw material costs. Our machine solves that problem using an A-B-C layer configuration, which allows up to 50% downgaugibility in finish thickness reduces polymer per sqr meter.

That means you reduce your virgin polymer use — and cut your raw material costs by up to 25%, all while maintaining premium outer-layer quality. It's smart engineering that speaks directly to your bottom line.

We don’t just promise output. We deliver it.

With a consistent output of 180 – 330 kg/hr, this machine helps you scale quickly. Whether you're supplying to greenhouse cultivators, contract farming groups, or industrial clients — this plant helps you take on more orders, meet tight timelines, and grow revenue confidently.

We don’t just promise output. We deliver it.

Every reel you produce will reflect your brand’s commitment to quality:

Glossy finish for market-ready packaging

Strong tensile strength for reliable performance in the field

Uniform thickness thanks to our State of Art Three layer Die-Head Technology.

This means fewer rejections, happier customers, and long-term repeat business.

Our customers often tell us: “This is the only machine in our plant that we don’t worry about.”

That’s because we use:

Japanese steel die heads

Plasma-nitrided screws with 72–74 HRC hardness

Heavy-duty force-cooled gearboxes

You get less downtime, low maintenance, and consistent production for years. The durability pays for itself.

From pre-installation planning to operator training and post-sales service, we walk with you at every step. We provide:

Smart remote diagnostics

Rapid-response service engineers

Onsite & virtual training

You’re not just buying a machine—you’re building a partnership with a company that cares about your success.

Thousands of film manufacturers around the world trust Shubham Extrusion to power their production.

It’s time you experienced that same confidence.

Let’s build your success — one film at a time.

Customers often ask what sets this machine apart from others on the market. The answer is simple — superior build quality, advanced layering precision, and reliable performance. Each layer of mulch film is evenly distributed, resulting in consistent thickness and durability — exactly what agricultural film users demand.

Our clients report significant improvements in production efficiency and reduced material waste. Thanks to smart extrusion controls and high-speed output, they’re able to meet growing demand without increasing operating costs.

They’ve also noted:

Yes! The machine is designed with the operator in mind. A user-friendly interface ensures minimal training is required, and preventive maintenance alerts help keep downtime close to zero.

Customers love that their teams can run it with confidence, even in 24/7 production setups.

“After installation, we were surprised at how fast we reached full production. Film quality was excellent from day one.” — Mr. Patel, Gujarat (Plastic Film Converter)

“This is one of the most stable machines we’ve used. The ROI is clear — high-quality output and very low maintenance.” — Ms. Iyer, Maharashtra (Agricultural Film Supplier)

If you're looking for a proven, high-performance mulch film line that delivers both technical excellence and commercial returns, this is the machine to consider. It’s not just a piece of equipment — it’s a long-term business asset trusted by industry leaders.